Machinery performance is a critical factor that directly impacts productivity and efficiency in industrial and manufacturing processes. One key aspect of ensuring optimal machinery performance is proper lubrication. Inadequate or irregular lubrication can lead to increased wear and tear, reduced operational life, and costly downtime for repairs. To address this challenge, many industries are turning to central lubrication systems as an effective solution. These automated systems provide a consistent supply of lubricant to all moving parts, eliminating the need for manual application and ensuring optimal machinery performance throughout operations. This article explores the benefits of central lubrication systems in improving machinery performance, highlighting their role in enhancing productivity, reducing maintenance costs, and prolonging the lifespan of equipment.

The Isohitech Central Lubrication System is an advanced and reliable solution designed to provide efficient and precise lubrication for machinery and equipment. With its state-of-the-art technology and customizable options, this system ensures consistent lubrication, reducing friction and wear on critical components. It streamlines maintenance processes, minimizing downtime and extending equipment lifespan. The Isohitech Central Lubrication System offers automated lubrication at regular intervals, promoting smooth machinery operation and enhancing overall efficiency. It is a cost-effective and user-friendly choice, delivering reliable lubrication for various industrial applications, ultimately optimizing productivity and performance.

The Importance of Machinery Performance

A central lubrication system plays a crucial role in optimizing machinery performance. One of the key benefits is the reduction of downtime due to maintenance and repairs. With a centralized system, lubrication is automated and continuous, ensuring that all critical components are adequately lubricated at all times. This minimizes wear and tear on the machinery, prolonging its lifespan and reducing the need for frequent repairs.

Another advantage of a central lubrication system is improved efficiency. By delivering precise amounts of lubricant to each moving part, friction is minimized, resulting in smoother operation and less energy consumption. This not only improves overall machine performance but also reduces operating costs. Additionally, proper lubrication helps prevent overheating by dissipating heat efficiently, preventing damage to sensitive parts and avoiding costly breakdowns.

Overall, investing in a central lubrication system is essential for maintaining optimal machinery performance. It not only reduces downtime and enhances efficiency but also saves money by extending the lifespan of equipment and minimizing repair costs.

Understanding Central Lubrication Systems

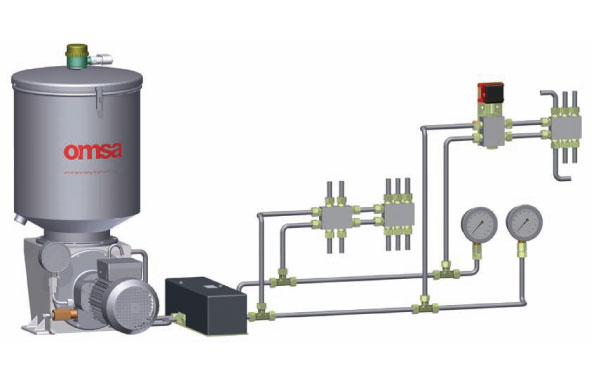

A central lubrication system is a mechanism that ensures the proper and efficient distribution of lubricants to various components of machinery. This type of system is designed to automatically deliver lubricant to different points, eliminating the need for manual lubrication. By doing so, it helps to minimize downtime caused by equipment failures due to lack of sufficient lubrication.

One key feature of a central lubrication system is its ability to provide consistent and precise amounts of lubricant. This ensures that all moving parts are adequately protected and reduces the risk of excessive or insufficient lubrication. Additionally, central systems help extend the lifespan of machinery by reducing wear and tear on critical components.

Centralized systems also offer several other benefits. They improve overall operational efficiency by reducing maintenance requirements and allowing for longer operating periods between maintenance intervals. Furthermore, these systems facilitate easier monitoring and control of lubricant usage through centralized management, making it simpler for operators to maintain optimal levels throughout their machinery.

In conclusion, understanding central lubrication systems is crucial in optimizing machinery performance as they provide consistent and precise amounts of lubricant while extending the lifespan of equipment. These systems also improve overall operational efficiency by reducing maintenance requirements and facilitating better monitoring and control over lubricant usage.

Enhanced Equipment Efficiency and Lifespan

One of the key advantages of implementing a central lubrication system is enhanced equipment efficiency and lifespan. By ensuring that all machinery components receive proper lubrication at the right intervals, friction and wear are significantly reduced. This leads to improved overall performance and increased productivity.

Moreover, a central lubrication system helps extend the lifespan of equipment by preventing premature breakdowns and minimizing maintenance requirements. When each component receives the necessary amount of lubricant, it operates smoothly and experiences less stress during operation. As a result, the chances of mechanical failure or damage due to inadequate lubrication are greatly reduced.

Furthermore, a well-lubricated machine not only performs better but also consumes less energy. With optimized friction levels, there is reduced power loss due to overheating or excessive wear. This translates into lower energy consumption and cost savings for businesses in the long run. Overall, implementing an efficient central lubrication system can have a profound impact on equipment efficiency, durability, and operating costs.

Reduced Maintenance Costs and Downtime

Reduced maintenance costs and downtime are significant advantages of implementing a central lubrication system for machinery. With a centralized system in place, the need for individual manual lubrication of various machine components is eliminated. This not only saves time but also reduces the chances of human error in lubrication, ensuring that each part receives the necessary amount of lubricant.

Moreover, a central lubrication system enables continuous and automatic lubrication while the machinery is in operation. This helps to maintain optimal performance by minimizing friction and wear on moving parts. As a result, the lifespan of machine components is extended, reducing the frequency of repairs and replacements.

In addition to cost savings from reduced maintenance requirements, implementing a central lubrication system also decreases downtime. Manual or intermittent lubrication methods often require machines to be shut down during maintenance activities, leading to production halts and loss of productivity. However, with continuous automatic lubrication provided by a centralized system, machines can operate for longer periods without interruptions for manual interventions or repairs – resulting in increased uptime and improved overall efficiency.

Improved Workplace Safety and Productivity

One of the key ways to improve workplace safety and productivity is by implementing a central lubrication system for machinery. This system ensures that all the moving parts of the equipment are properly lubricated, reducing friction and wear and tear. As a result, the risk of breakdowns or malfunctions is significantly reduced, leading to increased productivity as there are fewer instances of downtime due to repairs.

Furthermore, a central lubrication system also enhances workplace safety by minimizing the need for manual lubrication. With this system in place, employees no longer have to physically access hard-to-reach areas or operate machinery while applying lubricants. This reduces the chances of accidents or injuries caused by human error during maintenance procedures. As a result, workers can focus more on their core tasks without compromising their well-being.

Moreover, a well-maintained machinery through regular lubrication also contributes to improved workplace safety and productivity. Properly lubricated machines run more efficiently and smoothly, which not only extends their lifespan but also reduces energy consumption. This leads to cost savings in terms of both maintenance and utility bills while ensuring optimal performance throughout operations. By implementing a central lubrication system, businesses can create a safer work environment while simultaneously boosting productivity levels.

Environmental Benefits of Central Lubrication Systems

In addition to the numerous advantages that central lubrication systems offer in terms of machinery performance and maintenance, these systems also bring significant environmental benefits. One key environmental advantage is the reduction in lubricant waste. With a central lubrication system, precise amounts of lubricant are automatically dispensed at regular intervals, ensuring optimal lubrication without any excess or wastage. This not only helps conserve precious resources but also reduces the amount of hazardous substances released into the environment.

Another notable environmental benefit is the decrease in oil contamination and pollution. Traditional manual methods of lubricating machinery often result in oil spills or leaks due to human error or improper handling. In contrast, central lubrication systems employ closed-loop piping networks that eliminate the risk of accidental spills or leaks during routine maintenance tasks. By preventing oil discharge into soil, waterways, or drains, these systems contribute to preserving ecosystems and safeguarding water quality.

Central lubrication systems not only enhance machinery performance and prolong equipment lifespan but also play a crucial role in promoting sustainable practices by minimizing waste generation and preventing environmental pollution caused by improper lubrication methods.